Flame Polish

Flame Polish Overview

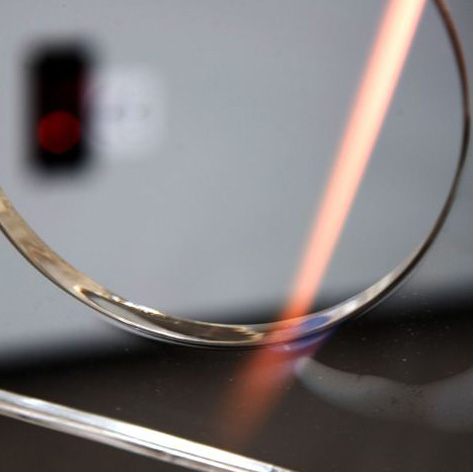

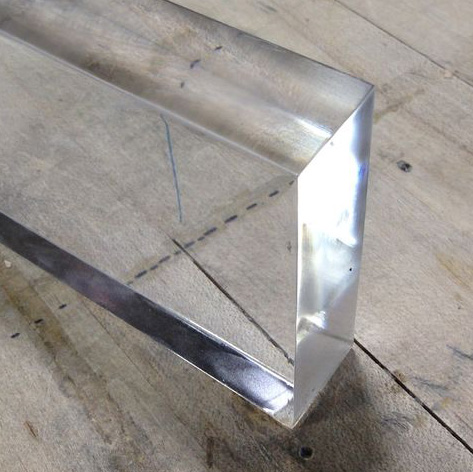

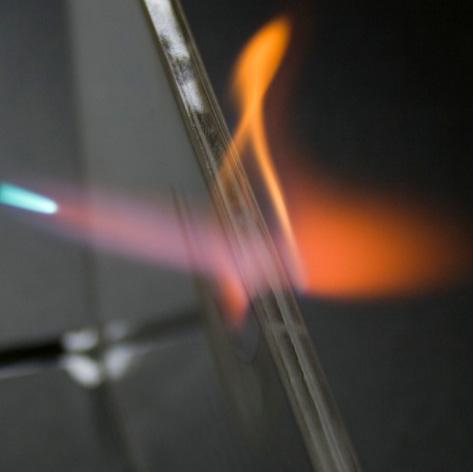

The process of flame polishing or fire polishing is not too dissimilar to diamond polishing; it creates super smooth edges usually on glass or thermoplastics by exposing it to a flame or heat. Operator skill is critical as it relies on precision timing. The area is heated and briefly melts, with the surface tension then smoothing the edge. This method is most applicable to flat surfaces, with curved or flat edges. It is frequently used in acrylic plastic fabrication due to the speed with which the process can be completed versus other abrasive techniques.

Flame polishing is ideal for those awkward to reach edges or complicated shapes. It results in a glass-like finish and particularly useful when used on acrylic, making it ideal for point of sale and display equipment

Uses and Limitations

Fabrication Uses

Flame polishing produces a transparent professional finish. It is as a result ideal for the use within point of sale, and display items.

Fabrication Limitations

Flame polishing is not suitable for all applications. Due to using heat, it is not possible to use this process in conjunction with some mounting and printing processes.