Once you have selected all the products you would like to quote and in what quantity, click submit quote request and we will respond to you as soon as possible.

Type the quantity required of this material and click “Add to Quote”

Materials currently in your list to quote:

No products in the list

Simply complete a few fields below and we will get back to you shortly!

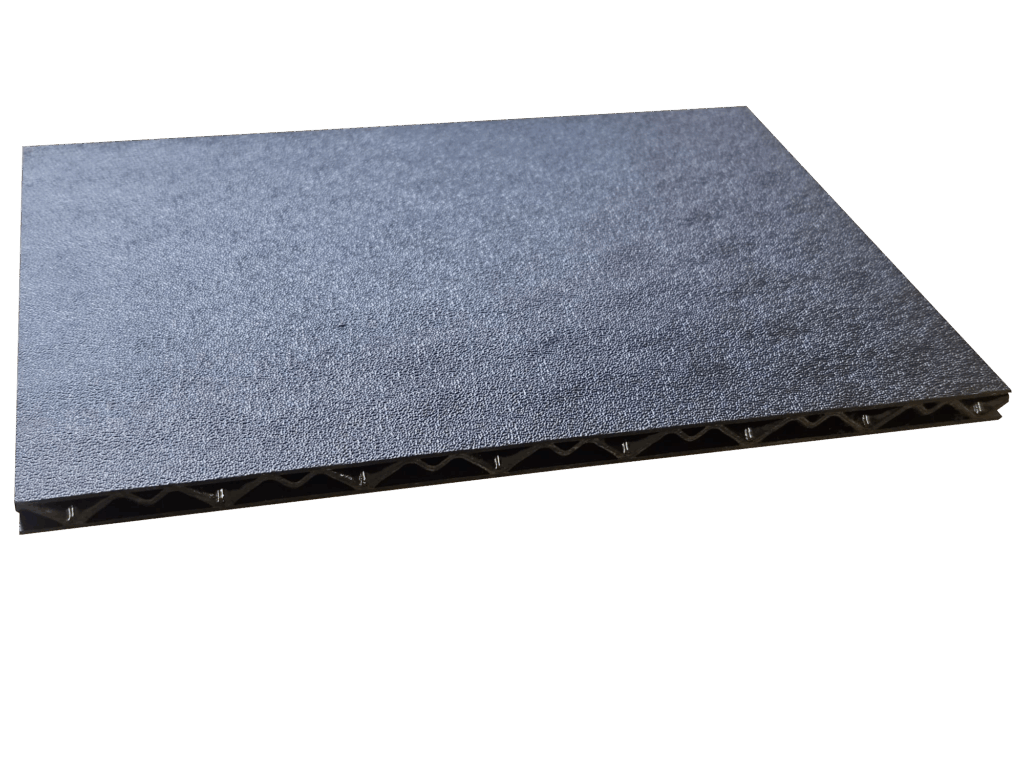

Finish Type / Pattern:

Pinseal

Thickness:

9mm (±0.3)

Width:

1220mm

Height:

2440mm

(Cut to Size options available!)

Recycled thermoplastic sandwich panel, thermoplastic core fused to thermoplastic skin laminate with a pinseal finish. Our lightest panel. Good for lightweight applications with wheel loads under 60kg per wheel.

| Product | Thickness (mm) | Weight (kg/m2) | Density (g/cm3) | Colour |

| RecoreLite® | 9.0±0.3 | 3.9 | 0.411 | Black |

Item

| Dimension (mm) | Tolerance (mm) | |

| Width | 1220 | ±3 |

| Length | 2440 | ±3 |

Texture

| Material | Anti-Slip Rating (Dry) | Anti-Slip Rating (Wet) | |

| Pin Seal | rABS | R10 | R10 |

Converting

Adhesive Bonding (Cyano-acrylates, Silicates) Welding

Screwing Drilling Riveting

Cutting (hand-held or mechanical saw) Routing

Mechanical Properties of raw Material*

| Property | Method | Unit | Result |

| Tensile Strength, Yield | ISO 37:2017 | MPa | 37.1 |

| Elongation, Yield | ISO 37:2017 | % | 2.7 |

| Flexural Modulus | ISO 178 | GPa | 2.02 |

| Izod Impact Strength | ISO 180 | kJ/m2 | 36.3 |

| Melt Flow Index | ISO 1133 | g/10min | 1.93 |

Thermal Properties of raw Material*

| Property | Method | Unit | Result |

| Melting Point | ISO 3146:2022 | °C | 260 |

| Heat Deflection

Temperature at 0.46 MPa |

ISO 75-2 | °C | 90.5 |

| Heat Deflection

Temperature at 1.8 MPa |

ISO 75-2 | °C | 89.6 |

| Flash Point | ASTM D1929 B | °C | 349 |

| Auto Ignition Temperature | ASTM D1929 B | °C | 508 |

| Thermal Expansion

coefficient |

ISO 11359 | mm/m°C | 0.0738 |

Mechanical Properties of Final Product**

| Property | Method | Unit | Result |

| Flexural Strength | ISO 178 | Nmm | 7.5×104±0.4×104 |

| Max Bending Moment | ISO 178 | N | 306±25 |

| Compression Strength | ISO 604 | MPa | 3.4±0.5 |

| Wheel Compression, Limit

Load (Ø80x25mm) |

Internal | kg | <66 |

* Values taken from MatWeb database for ABS sheet.

**Average values taken in house with 3 point bending and flat platen compression. Flexural Strength calculated as a bending moment per mm of sample width.

Chemical Resistance

Resistant to aqueous acids, alkalis, hydrochloric and phosphoric acids as well as animal, vegetable, and mineral oils. Do not use with aromatic hydrocarbons, glacial acetic acid, or carbon tetrachloride. It is attacked by concentrated sulphuric and nitric acid.

Clean with water or with Isopropyl Alcohol, DO NOT clean with Acetone based products.

Environment

RecoreLite® is a non-biodegradable product.

Recycling Properties

Hereby, we confirm that our products are based on rABS which is 100% recyclable and is widely recycled.

Mechanical Recycling

RecoreLite® can be reground, and re-pelletised ready for re-extrusion (currently done on our own production waste).

We offer a free take back scheme for this product if you are unable to recycle it yourself, please contact us for more information.

The information provided in all product advice, safety data and technical data sheets is to the best of our knowledge correct but not all-inclusive and without warranty and is to be used solely as a guide. Similarly, all technical advice, whether verbal, in writing, or as a result of sample trials, is for guidance and is given in good faith but without warranty, since site conditions and care and skill of application are beyond our control. Every effort to ensure the accuracy of the images of our products has been made, however, the accuracy of the colours may differ and vary.

Eagle Plastics

3 Highmeres Road,

Thurmaston,

Leicester,

LE4 9LZ

Call our team on

0116 276 6363

Or email us

enquiries@eagleplastics.co.uk

Cookies Policy

Copyright © 2024 Eagle Plastics – Proud to be part of the Plastribution Group of companies.