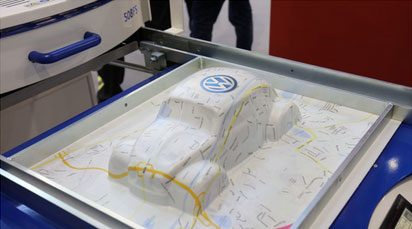

Vacuum Forming

Vacuum Forming Overview

Vacuum forming may be one of the oldest methods of processing plastic materials (it dates back to the 1930’s) but even today there is no alternative to match the low cost and speed of tooling compared to injection moulding. It still has its place, and when combined with new technologies such as 3D printing, brings a multitude of possibilities.

Whilst not every design or shape is suitable for vacuum forming it is used for the most diverse range of plastic processing applications. Companies and industries involved in film and theatre stage production, schools, automotive and aerospace are all high users of the vacuum forming process.

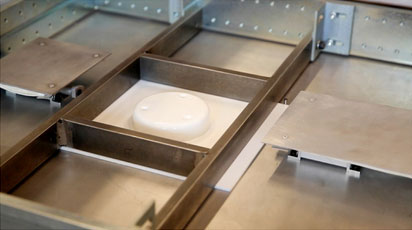

Which of the thermoplastic sheets we stock can be used to vacuum form;

- Polystyrene (HIPS)

- Acrylonitrile Butadiene Styrene (ABS)

- Acrylic Capped ABS

- PETG

- Polypropylene

- Polyethylene (HDPE)

Uses and Limitations

Vacuum Forming Uses

Vacuum forming offers a range of benefits to manufacturers with high volume capability and ability to store sheets in bulk. When combined with line bending equipment, it’s possible to create three-dimensional products such as more complex Point of Sale (POS) displays, TV and speakers.

It is endlessly adaptable and perhaps most visibly used in display marketing, and promotional items.

Uses and Limitations

Vacuum forming offers a range of benefits to manufacturers with high volume capability and ability to store sheets in bulk. When combined with line bending equipment, it’s possible to create three-dimensional products such as more complex Point of Sale (POS) displays, TV and speakers.

It is endlessly adaptable and perhaps most visibly used in display marketing, and promotional items.